Poly-Tungsten

Depending on the polymer matrix, Poly-Tungsten can vary in character from rigid to flexible. Some of the materials we use in Poly-Tungsten include PA – polyamide, PSU – Poly-sulfone, LCP – Liquid Crystal Polymers, and TPU – Thermoplastic Polyurethane.

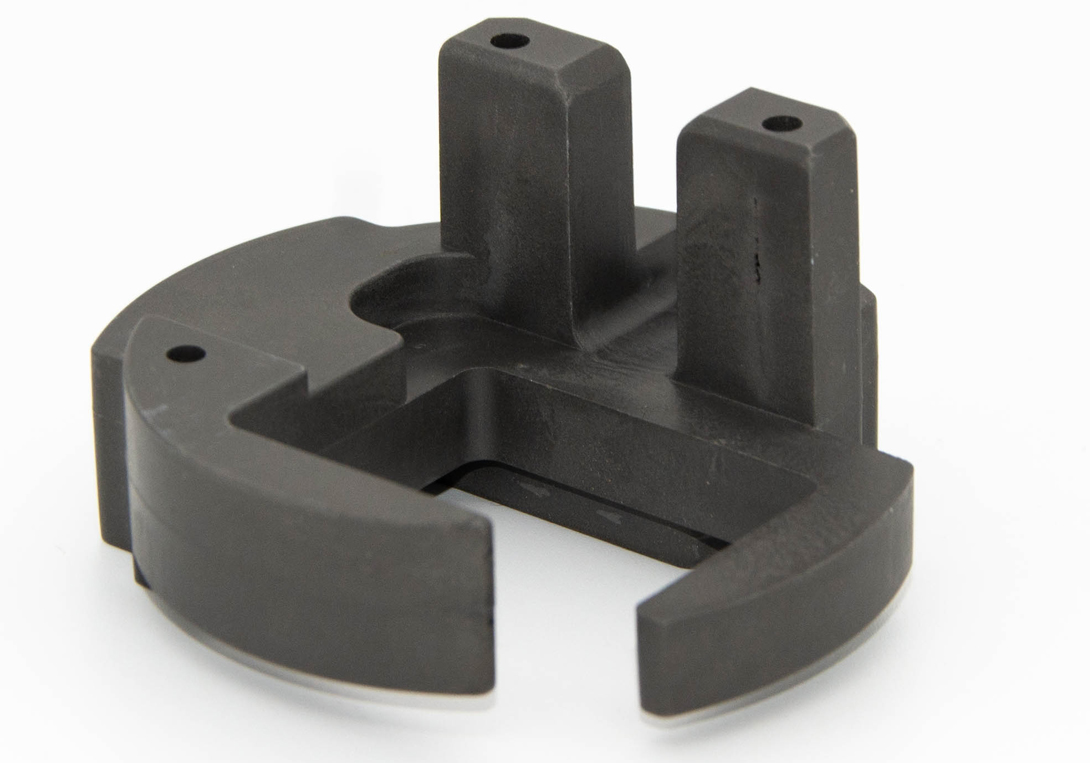

Poly-Tungsten is produced by combining the material groups: Polymer and Tungsten. Poly-Tungsten is a matrix of polymer resins with tungsten, manufactured in a one-step process through Tungsten Injection Molding (TIM) to produce a final product. Engineered to suit the application requirements, we can produce products that weigh up to 200 grams with a density ranging from 3 to 13 gr/cm3.

Our one-step, net-shape manufacturing process provides significant cost advantages for our customers, and the result is a nonhazardous product with excellent mechanical properties for ionizing radiation shielding. Poly-Tungsten is inherently opaque and thus impervious to ionizing radiation, making it a viable alternative to lead which has well-documented health risks.

Radiguard™ manufactures complex shaped Poly-Tungsten radiation shields for medical devices, nuclear medicine, and radiography machinery.

Across the density range of Poly-Tungsten solutions (3-13 gr/cm3), the mechanical ionizing radiation shielding properties are maintained due to the high atomic number in Tungsten. This gives us the flexibility to select the density by assessing the engineering and cost-effective requirements for each project.

ADDITIONAL APPLICATIONS

The high density of Poly-Tungsten also makes it ideal for weight-balancing applications in a variety of aviation, aerospace, and commercial and retail goods such as sport products, clocks, and gyroscopes.

Due to Poly-Tungsten’s non-magnetic and high electrical conductance properties, it also has heat sink applications in microelectronics.